Technologies

Pneumatic

Electromagnetic

Software

Integrated traceability software with color touchscreen

Electromagnetic & pneumatic

100 x 120 mm

Plastics and metals

- TOUCH & MARK

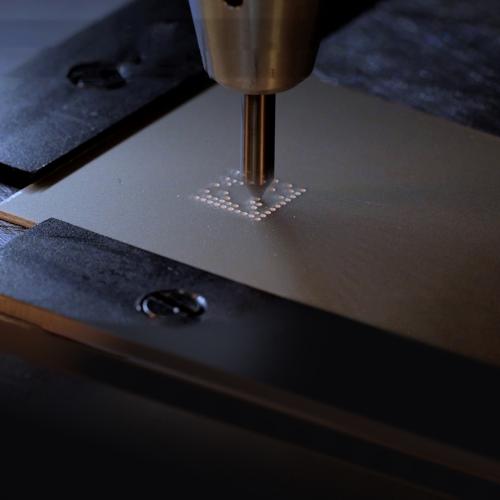

The large color touchscreen and onboard control software make training a thing of the past. The intuitive system allows you to start marking text, logos and 2D codes straight away. Also metal plate engraving makes it the best engraving machine for metal. It makes the operator’s life easy and does not require a computer.

- I-SENSE DOT PEEN MARKING STATION

The I-Sense function (Impact eZ m) detects the surface of the workpiece, automatically adjusts the height of the Z-axis and starts marking with no intervention on the part of the operator. Several adjustment modes are available: automatic mode (I-Sense), programmable mode and normal mode, which allows manual adjustment.

- DYNAMIC DOT CONTROL

Obtain a perfect result every time with the IMPACT DDC™ (Dynamic Dot Control, on Impact m and eZ m) feature, a technology which enables automatic adjustment of point density according to the required size and depth of marking.

Technical Specifications

Available in two power sources

Pneumatic (p) - Requiring compressed air

Electromagnetic (m) - Electric version

Available with manual or motorized Z-axis

Pneumatic (eZ p) and Electromagnetic (eZ m)

Multiple stylus available for all your marking environments

Accessories available

- Rotary devices

- Automatic plate feeders

Support USB barcode and 2D code readers for the read-and-mark-and-check process.

File transfer via USB stick or network connection (FTP)

The markings comply with international standards

Data Matrix™ ECC200, GS1 Datamatrix, 5x7 font, DT05-89, JES 131, ATA Spec 2000, UID, SAE AS9132, NASA-STD-6002, MIL-STD-130, ISO/TS 16949, AIAG B-17, AIAG B-4, ISO/IEC 16022, AIM-DPM etc.

General

Marking Capacity

Marking area

100 mm (3.9 in) x 120 mm (4.7 in)

Z axis stroke

300 mm (13 in)

Z axis type

m & p: Manual

eZ m & eZ p: Motorized & programmable

The IMPACT dot peen engraver range, is a small engraving machine that makes it possible to perform high-quality marking on a large number of materials from, metal plate engraving (painted steel, aluminum, brass, iron, steel, raw, and anodized aluminum) to plastics (ABS, PA, PP).

From single part markings to small batches the IMPACT is loved for it size and versatility. With a 11.81 in clearance and open architecture traceability on, one of the smallest parts to identification on larger heavier parts are available. No job is too big. Used by automotive, aerospace, medical, and from heavy and light industries, the Impact small engraving machine has become a favorite workstation.

We took all of our experience working within industrial traceability and created the IMPACT for maximum flexibility, when both marking requirements and parts to be marked are constantly changing.

The IMPACT was created to be the all in one, ready to go solution, with usability at the forefront and designed to be opened and ready to start marking immediately.

This dot peen marking machine can handle more than 25 materials

| DOT PEEN | |

|---|---|

| PLASTICS | |

| ABS | |

| PA | |

| PC | |

| PE, BET | |

| PMMA, Acrylic | |

| POM - PBT | |

| PP | |

| METAL | |

| Aluminum | |

| Anodized Aluminum | |

| Brass | |

| Carbide | |

| Coated metal | |

| Copper | |

| Gold, silver, nickel, platinum | |

| Stainless steel | |

| Steel | |

| Titanium | |

Other content you might like

IMPACT: modern machine, historical robustness

Technifor started to manufacture benchtop dot peen machines 40 years ago

Our historical brand Technifor invented dot peen, a new marking technology, only four years after being founded in 1985. The CN machine range was quickly launched following the dot peen invention. These standalone marking machine allowed busy workshops and part manufacturers to easily identify all kinds of small to medium-sized industrial items.

In 2008 Technifor released the XF500 standalone marking machine which inherited from the robust mechanics of the dot-peen “CN” range.

Designed for worshops, this stand-alone marking solution has enabled parts manufacturers to easily identify all kinds of small and medium-sized industrial parts.

At the same time, Propen, a distribution brand of the Gravotech Group, developed the worldwide famous P5000 standalone engraver. When Technifor and Propen joined forces in 2018, the XF500 and P5000 evolved into the IMPACT standalone engraver, a modern, industrial, and robust marking machine, field-proven for the industry.