Laser cutting and engraving are key technologies for personalization, product creation, industrial identification (especially traceability), and signage. These processes offer high precision and adaptability, making it possible to create unique objects, engrave parts (logos, texts, numbers, codes, etc.), or create signage.

Laser cutting and engraving are versatile and can be used in a wide range of fields… Discover the many applications.

How do laser cutting and engraving work?

Laser engraving

For sharp, defined results

Laser engraving is a precise technology that removes a thin layer of material to create a depth effect. It is particularly suited for reproducing images, logos, or typography and can be applied to a variety of materials, including wood, plastic, glass, metal, and leather. The possibilities are vast!

There are two main laser engraving techniques for objects:

- Raster engraving - line-by-line or point-by-point engraving.

- Vector engraving - geometrical engraving, which requires more time.

Laser cutting

For precise, clean shapes

Laser cutting is based on a thermal separation process in which the laser beam passes entirely through the material to create shapes.

This technology can be used, for example, to cut embossed letters for signs, labels, directional signs, precious metal jewelry in very thin layers, or precise models in wood, cardboard, or plastic.

Which laser sources for which application?

| SOURCE | KEY APPLICATIONS |

| CO2 | Cutting and engraving on various materials (wood, acrylic…) for the personalization sector (gifts, decorations…) and signage (plaques, labels, panels…). |

| Fiber | Metal marking to ensure industrial traceability directly on parts (Direct Part Marking or DPM) and personalization of precious metals. |

| Green | Cold marking, highly effective on many sensitive plastics and precious metals used for industrial personalization or identification. |

| MOPA | More versatile than fiber lasers, it enables fine settings (adjustment of pulse duration and frequency) and engraving of more materials (metals, fine plastics, etc.), with notably better results on plastics. |

Laser cutting and engraving: examples of applications

Product personalization

Laser engraving is essential for transforming ordinary objects into unique creations, such as personalized gifts or promotional items. The precision and finesse of engraving deliver precise results on a wide range of materials: precious metals, stainless or anodized steel, wood, glass, paper, leather, or acrylic.

When it comes to personalization, laser engraving can mark a wide range of objects, including:

- Wine and spirit bottles.

- Gifts as pens or water bottles.

- Jewelry (e.g., medallions and pendants).

- Perfume bottles and cosmetics.

Laser engraving can also be used to personalize key rings or decorations in wood or acrylic.

Identification and traceability

Laser engraving is the solution for product identification and traceability, and with good reason. It enables durable marking of information on parts for clear, permanent identification throughout their life cycle.

Its application is key in many demanding sectors, such as medical, automotive, and aeronautics, to guarantee conformity, safety, and optimal product management. Compatible with a wide variety of materials (steel, plastic, stainless steel, aluminum), it is THE versatile solution for diverse identification needs:

- Tools for precise tracking and simplified inventory.

- Laser cutting can be used on automotive, medical, or aeronautical parts to ensure traceability and compliance with safety standards.

- Manufacturer plates.

Signage

Signage is key in informing and guiding people around a place or space. Laser cutting and engraving can be used to create customized signage elements, using a variety of materials such as plastic, acrylic, wood, anodized aluminum, or paper.

There are numerous applications for personal, normative, directional, and industrial signage:

- Door signs (acrylic or metal) for offices or mailboxes.

- Plates and labels to identify installations or secure equipment.

- Distribution panels, terminals, or switches.

- Maintenance labels, resistant to harsh environments, used for tracking interventions.

- Directional signs to guide you through facilities, factories, or public places.

- Customized displays and signs.

Object creation

Laser cutting and engraving allow the creation of objects with complex shapes and high precision. Flexible in designing and realizing various objects, they are the perfect solution for those who wish to create unique items.

In creative applications, laser cutting and engraving can be applied to:

- The manufacture of objects in wood, acrylic, or paper (decorations, gifts, toys, coasters, decorative boxes...).

- The creation of personalized awards.

Laser cutting and engraving machines for your projects

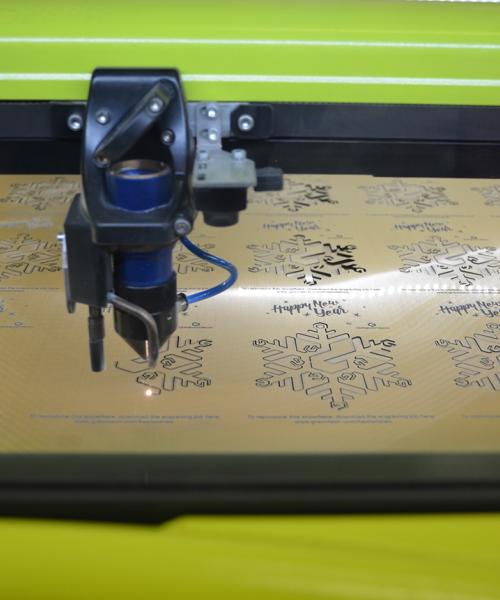

Laser cutting and engraving machines, like Gravotech laser tables, are designed for a variety of materials. They are available with CO2, Fiber, and Edge laser sources (depending on the model), perfect for your creative, signage, or industrial projects.

- LS100 is a compact and versatile laser cutting and engraving machine, ideal for customization projects and small series.

- LS100EX for processing medium-sized substrates.

- LS900 for large-scale production or simultaneous engraving of multiple plates.

- LS1000XP is powerful and fast, suitable for large production runs or complex projects on various materials (wood, acrylic, or cardboard).

Small CO2 laser engraver and cutter for personalization, signage and creative.

LS100

Medium CO2 or Fiber laser engraving and cutting machine for signage and small series.

LS100 EX

Large laser engraver and cutter that can do everything.

LS900

Extra large laser engraving and cutting machine for high productivity.

LS1000XP

Our laser stations are designed to deliver exceptional precision in even the smallest spaces, while ensuring high engraving quality and notable speed compared to laser tables. These laser cutting and engraving machines are available with all Gravotech laser sources - Hybrid, Green, Fiber (except CO2, which is only available with the WeLase™ station).

Designed with industry in mind, our laser machines can be integrated into production lines for precise, automated marking. They are available with all Gravotech laser sources: Fiber, Green, Hybrid, and CO2.

These versatile, high-performance solutions guarantee optimum traceability for the electronics, automotive, and medical sectors.

Integrated laser system to mark and engrave on all metals.

FIBER laser

Integrated laser system for high quality and cold marking on plastics and precious metals.

GREEN Laser

Integrated laser system for high quality marking on plastics and metals.

HYBRID laser

Integrated laser system to mark organic materials.

CO2 laser

For object personalization, industrial identification, and professional signage, laser cutting and engraving offer a wide range of possibilities for creating unique, high-quality parts. Thanks to their precision, speed, and adaptability, these technologies can meet the most exacting requirements and bring your most ambitious projects to fruition. Would you like to find out more?